In the modern social market, the more profile of industrial production, the more traditional crusher technology has not fully met the needs of the market, then we will learn more about the traditional crusher and the new technological ultrafine crusher after technology innovation.  With my country's continuous improvement and improvement in crushing technology in recent years, the birth of ultrafine pulverizer has solved a lot of problems in all walks of life, and the new ultra-microfiner has reached its comprehensive performance. It is possible to fully comply with the modern process of crushing demand, and its wide application and excellent performance quickly accepted by various industries. The ultrafine pulverizer is different from the traditional pulverizer. The ultra-fine pulverizer is not a pulverizer that can make a fine particle is a super-slice, because most crushers are traditional significance to smash the material, such as ore, cereals, etc. Moreover, the right to fineness is not high, generally 100 mesh, no ultrasound concept. Moreover, the pulverization phenomenon is used as a decrease in wear during the pulverization process, and the disadvantage of the heating is reduced as much as possible. Therefore, during the design and use of traditional crushers, try to reduce the fine powder content, which can reduce the heat of the machine to reduce the wear of the pulverized part. Add material flow. Therefore, this type is not suitable for use in ultrafine pulverizer for use by the general pulverizer to increase the speed, reduce the transformation of the pulverized gap. If this kind of crusher is used to use ultrafine pulverizer, it will inevitably be heated, too much wear, and the motor is easily damaged. The reason is that the machine is in a super conventional working condition. This phenomenon is often encountered in the Chinese medicine pulverizer.

With my country's continuous improvement and improvement in crushing technology in recent years, the birth of ultrafine pulverizer has solved a lot of problems in all walks of life, and the new ultra-microfiner has reached its comprehensive performance. It is possible to fully comply with the modern process of crushing demand, and its wide application and excellent performance quickly accepted by various industries. The ultrafine pulverizer is different from the traditional pulverizer. The ultra-fine pulverizer is not a pulverizer that can make a fine particle is a super-slice, because most crushers are traditional significance to smash the material, such as ore, cereals, etc. Moreover, the right to fineness is not high, generally 100 mesh, no ultrasound concept. Moreover, the pulverization phenomenon is used as a decrease in wear during the pulverization process, and the disadvantage of the heating is reduced as much as possible. Therefore, during the design and use of traditional crushers, try to reduce the fine powder content, which can reduce the heat of the machine to reduce the wear of the pulverized part. Add material flow. Therefore, this type is not suitable for use in ultrafine pulverizer for use by the general pulverizer to increase the speed, reduce the transformation of the pulverized gap. If this kind of crusher is used to use ultrafine pulverizer, it will inevitably be heated, too much wear, and the motor is easily damaged. The reason is that the machine is in a super conventional working condition. This phenomenon is often encountered in the Chinese medicine pulverizer.  Applying in the condiment industry, the ultrafine pulverizer can make multi-functional regulation, is the most important crushing equipment in the food industry, as it does not cause any pollution, clean hygiene, such as instant noodles. In the chemical raw material industry, the ultrafine pulverizer can maintain normal temperature under mechanical exercise, minor and uniform, reduce industrial depletion, and have long production efficiency. The ultrafine pulverizer can be applied to the pulverization process in the aquatic feed industry, and the ultrafine pulverizer exhibits its advantages of facilitating the non-residue and can effectively prevent the material. In the crushing of the aquatic feed, the degree of meticulosis of its particles is often high, so the ultrafine pulverization technique can reach the crushing effect, more uniform. The ultrafine pulverizer can be applied to various types of fruit vegetables for dehydrated pulverization, the main feature is not to produce a large amount of warmth during the production process, resulting in a large amount of thermal bonding. In agricultural and sideline products,The machining of all kinds of soil special products is simple and convenient to operate, suitable for home workshops. The application of the ultrafine pulverizer is also widely popular in various minerals industry, ceramic industries, carbon powder industries, etc.

Applying in the condiment industry, the ultrafine pulverizer can make multi-functional regulation, is the most important crushing equipment in the food industry, as it does not cause any pollution, clean hygiene, such as instant noodles. In the chemical raw material industry, the ultrafine pulverizer can maintain normal temperature under mechanical exercise, minor and uniform, reduce industrial depletion, and have long production efficiency. The ultrafine pulverizer can be applied to the pulverization process in the aquatic feed industry, and the ultrafine pulverizer exhibits its advantages of facilitating the non-residue and can effectively prevent the material. In the crushing of the aquatic feed, the degree of meticulosis of its particles is often high, so the ultrafine pulverization technique can reach the crushing effect, more uniform. The ultrafine pulverizer can be applied to various types of fruit vegetables for dehydrated pulverization, the main feature is not to produce a large amount of warmth during the production process, resulting in a large amount of thermal bonding. In agricultural and sideline products,The machining of all kinds of soil special products is simple and convenient to operate, suitable for home workshops. The application of the ultrafine pulverizer is also widely popular in various minerals industry, ceramic industries, carbon powder industries, etc.

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

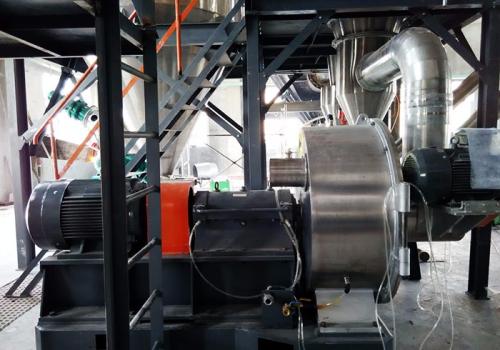

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line