The ultrafine pulverizer is sometimes installed in a certain place in a certain place. Today we have summarized six ways to avoid the chance of installing details, then let's take a look!  There are many components above the dosing unit, there is a measure of pumps, safety valves, back pressure valves, dampers, etc., then the pharmaceutical device is in the field installation process, every detail must be considered, if a link appears The problem will bring unexpected results, and the drug pay attention to this 6 aspects during the installation of the pharmaceutical device to ensure the stability of the dosing unit. 1. Check if the feet platform of the pharmaceutical device is on the same horizontal line (no need to install the foot bolt), the pumped port is wire buckle joint, quick joint, flange joint, pick the corresponding joint, connect the power supply . 2. Before doing good exercises, the measurement pump transmission box is inserted into an appropriate L-CKE460 worm gear oil and L-CKC460 industrial closed gear oil, which is subject to oil level horizontal. 3, automatic or manual filling medicine, press power, electric control cabinet, the power indicator is on the power source to turn. Press the stirring tank to twisting, the mixer starts working for 3-5 minutes, open the pipe valve, open the flow control valve, press the metering pump to start pressing, and the metering pump begins. 4. To regularly check if the metering pump is blocked, clean the pipeline, filter, to prevent clogging. 5. Regularly check the stirring device, check if the stirring shaft is flexible, whether the impeller is twisted, whether the coupling is loose, so that the shaft torque is too large and the agitation power is consumed. Damage should be replaced in time. 6. In the pharmaceutical device, it is necessary to check the safety valve, pressure gauge and the valve valves periodically to avoid leakage events. Use pumps or multi-pump, which should be used alternate to avoid long-term start or disable the same pump.

There are many components above the dosing unit, there is a measure of pumps, safety valves, back pressure valves, dampers, etc., then the pharmaceutical device is in the field installation process, every detail must be considered, if a link appears The problem will bring unexpected results, and the drug pay attention to this 6 aspects during the installation of the pharmaceutical device to ensure the stability of the dosing unit. 1. Check if the feet platform of the pharmaceutical device is on the same horizontal line (no need to install the foot bolt), the pumped port is wire buckle joint, quick joint, flange joint, pick the corresponding joint, connect the power supply . 2. Before doing good exercises, the measurement pump transmission box is inserted into an appropriate L-CKE460 worm gear oil and L-CKC460 industrial closed gear oil, which is subject to oil level horizontal. 3, automatic or manual filling medicine, press power, electric control cabinet, the power indicator is on the power source to turn. Press the stirring tank to twisting, the mixer starts working for 3-5 minutes, open the pipe valve, open the flow control valve, press the metering pump to start pressing, and the metering pump begins. 4. To regularly check if the metering pump is blocked, clean the pipeline, filter, to prevent clogging. 5. Regularly check the stirring device, check if the stirring shaft is flexible, whether the impeller is twisted, whether the coupling is loose, so that the shaft torque is too large and the agitation power is consumed. Damage should be replaced in time. 6. In the pharmaceutical device, it is necessary to check the safety valve, pressure gauge and the valve valves periodically to avoid leakage events. Use pumps or multi-pump, which should be used alternate to avoid long-term start or disable the same pump.

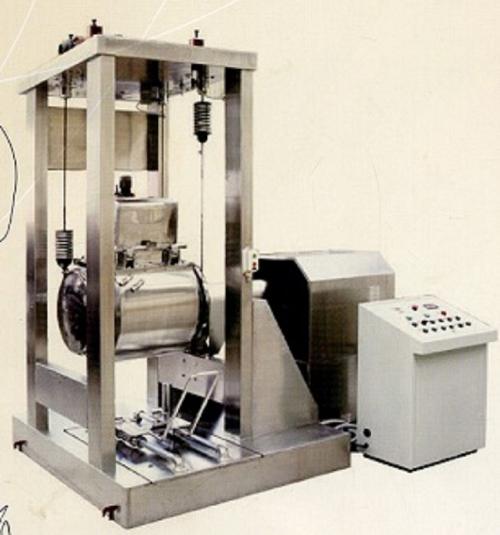

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line