Advantages of eddy turbo mills when used as coating modification.

It can crush all kinds of materials with Mohr hardness less than 3. The comminution rotor is composed of multi-layer comminution disk and multiple comminution knives, with high comminution efficiency. The blade is made of wear-resistant alloy and can be r

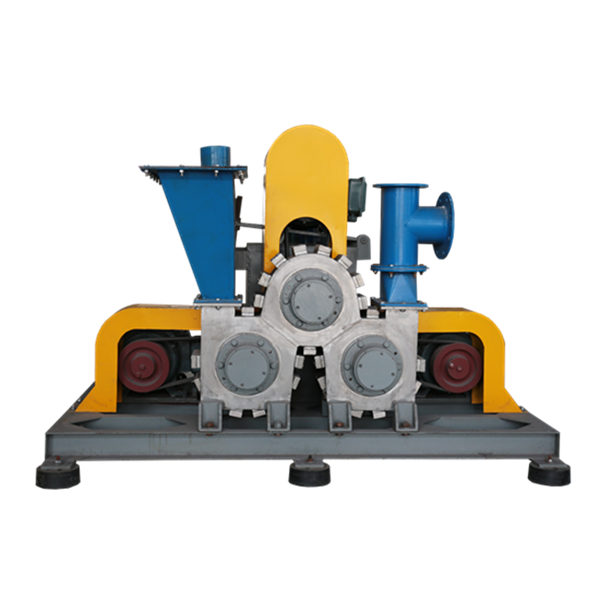

The drying and dispersing modified rotor mill is a very efficient mechanical mill with multiple rotors on its vertical shaft. Multi-layer grinding cutter head, strong shearing force and breaking power, can be connected to hot air source for multiple purpo

Through the relative motion of three rotors to change the effect of cyclone and vortex, the powder surface is coated. No heating device, low investment and low operation cost.

Set drying and grinding function integration, high efficiency, low operating cost, can withstand 400 ℃ high temperature into the bearing using heat insulation design. The grinding block and grinding lining can be replaced. The grinding block of different

As a new type of efficient pulse dust collectors improved based on bag filters, the pulse dust collector features higher dust collection efficiency, stronger adaptability and longer service life, widely used in dust separation and material recycling of no

The rotary dryer can be used to dry the slag, clay and pulverized coal from the building material or metallurgical industry as well as the leaching residue during metal beneficiation and other materials, characterized by strong adaptability, widerange of

With the unique restart sleeve and cut-off switch, the material is clean and filled with high speed, which can better control the dust leakage for the powder with higher dust emission and provide a more effective logistics form.

The gas box pulse bag type dust collector is the advantages of the collector such as the back blowing and jet pulse in the collection chamber.