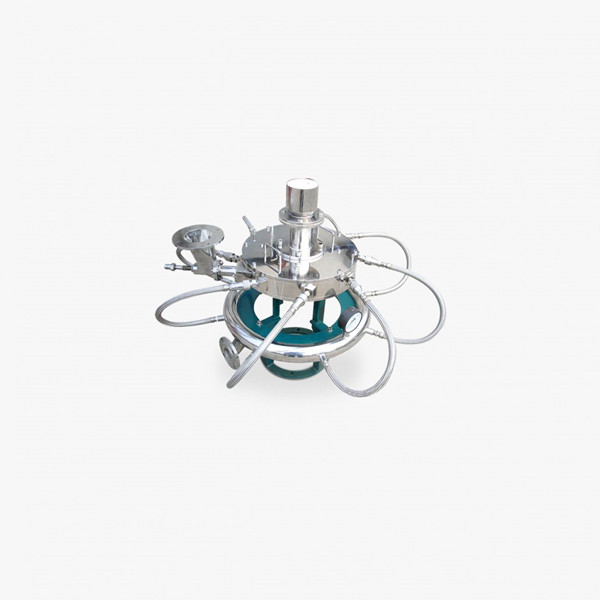

At present, Spiral Jet Mill is widely used in the pharmaceutical industry, with the characteristics of simple structure and easy cleaning, gradually replacing other types of air flow pulverizer

Product Size: D50:1.5-45μm

Production Capacity: 5~6000kg/h

Feed Size: <5mm

Material Handling: API (cephalosporin), graphite / resin, silica powder, pesticide (imidacloprid), soybean peptide, iron dextran,etc

Reading Volume:

marketing@alpapowder.com

The grinding compressed air enters into the grinding chamber and passes through a certain number of grinding nozzles with a specific angle to produce a high-speed spiral air flow. The material is accelerated into the grinding chamber through the nozzle. Driven by the spiral airflow, the material rotates repeatedly in the grinding chamber at high speed. Because of the different speed, the particles collide with each other, resulting in the crushing effect. Due to the movement of the spiral, the grading effect is produced, and the particles small to a certain extent can be discharged with the air flow and enter the collection device (such as cyclone separator or filter). Coarse particles continue to move in the grinding chamber until they reach a certain fineness.

It is suitable for dry grinding of all kinds of materials with Mohs hardness below 9, especially for grinding of materials with high hardness, high purity and high added value;

Constant temperature or low temperature grinding without medium, especially suitable for the grinding of heat sensitive, low melting point, sugar and volatile materials;

The particle size of the product is d50:2 ~ 100 μ M can be adjusted arbitrarily;

No rotating parts, easy to disassemble and clean;

The main body of the main engine is made of a whole steel plate by CNC processing, without welding seam;

Easy implementation of CIP and sip.

European technology, special for pharmaceutical, in line with GMP and FDA certification requirements;

It can meet the requirements of class B and class D of GMP workshop;

The functions of CIP and sip can be customized according to the requirements;

High pressure crushing and self classification structure design, the product particle size is up to 1 ~ 5um;

Static production, no power rotating parts, easy disassembly and cleaning;

More than 5g feed can achieve ultrafine grinding and collection, which can meet the needs of small batch research and experiment;

Main machine positive pressure crushing, almost no residue, ensure high collection rate of 99%;

Full welding is adopted for all welds, with arc transition and easy to clean;

Equipment design structure: easy to clean, easy to disassemble and assemble, passivation treatment;

It can be integrated into the isolation hood for materials with strong activity;

for sticky materials, anti sticking technology can be selectively applied to easy to stick parts;

Provide 4q verification documents;

The Spiral Jet Mill uses compressed gas to bring the raw materials into the pulverizing chamber through the feeding ejector, and under the drive of the high-speed air flow from multiple nozzles, the raw materials are sprayed on the pulverizing wall in a tangent way, so as to achieve the effect of friction pulverization. The grinding fineness can be controlled by adjusting the longitudinal depth of the grinding chamber, the grinding pressure or the feeding speed. Compared with the fluidized bed air pulverizer, the controllability of grinding fineness is poor.

| Parameters/specifications | MQPW06 | MQPW10 | MQPW15 | MQPW20 | MQPW30 |

| Feed Size(mm) | <2 | <3 | <3 | <3 | <3 |

| Product Size(d97:μm) | 8~150 | 8~150 | 8~150 | 10~150 | 10~150 |

| Production Capacity(kg/h) | 10~200 | 20~400 | 50~800 | 150~1500 | 300~2000 |

| Air consumption(m3/min) | 6 | 10 | 15 | 20 | 30 |

| Air Pressure(Mpa) | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 |

| Installed Power(kW) | 30~37 | 65~85 | 85~100 | 120~142 | 175~200 |

Note:The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.