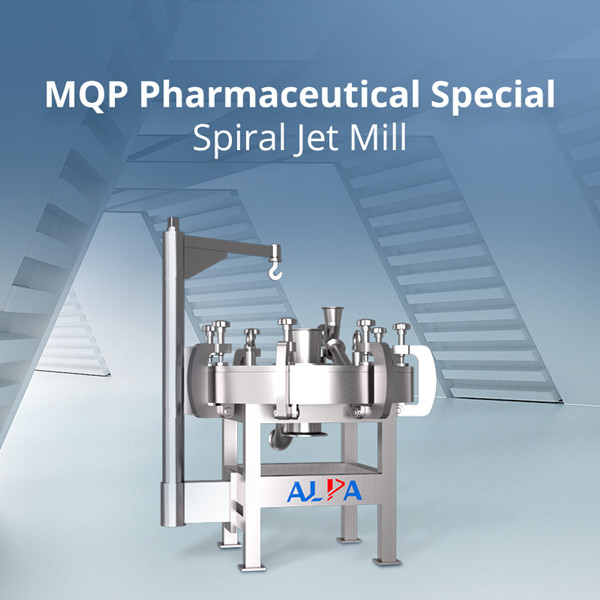

Compared with the fluidized bed air flow mill, the Pharmaceutical Special Spiral Jet Mill has a good crushing effect on viscous materials, and the crushing process will not produce the phenomenon of blocking material and unable to crush.

Product Size: D50:1.5-45μm

Production Capacity: 5~6000kg/h

Feed Size: <5mm

Material Handling: Nano silica, lithium iron phosphate, celecoxib, zirconia, barium titanate, pesticide, carbon powder, polytetrafluoroethylene, ternary material, silver powder aggregate, modified silica, inorganic pigment, API (cephalosporin),etc

Reading Volume:

marketing@alpapowder.com

The main machine is equipped with centrifugal classification device, which can not only complete crushing, but also has classification function. The wind type centrifugal shearing, no screen, no net, powder particles can be adjusted at will. After crushing, the materials are transported to the outlet of discharge valve by negative pressure to meet the product requirements, It is widely used in chemical industry, dyestuff, coating, medicine, food and other industries in different fields. The crushing and grading of materials to finished products are carried out in the same closed system. After dust removal treatment, it does not pollute. It is an ideal complete set of equipment for current environmental protection.

Available particle size D50:1.5-45μm.

Seamless and smooth design, easy disassembling and cleaning.

Free of transmission parts, self-classifying structure.

Good particle shape, narrow particle size distribution.

CIP/SIP design is optional.

Meet GMP/FDA requirements.

Constant temperature or low temperature, medium-free grinding, especially suitable for materials of heat sensitive, low melting point, sugary, volatile nature.

The grinding process is completed by the collision of the materials themselves., Fully self-grinding, so this device is durable and products purity is high in contrast.

Could lining with ceramic internal of Mill, ensuring non-contact with metal throughout the grinding for high purity of the final product.

Achieve explosion-proof design, no safety hazards, cleaning is very simple, easy to disassemble and replace parts.

Grinding is in closed system, low dust and noise, clean and environmentally friendly.

PLC control system, easy operation.

Optional explosion-proof design, can also be upgraded to nitrogen circulation system to meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials.

Pharmaceutical jet mill(Medical jet mill, Pharmacia jet mill, pharmacy jet mill) works with cyclone, bag filter and suction fan to form a complete grinding line. Compressed air flow after filtration and drying would go into milling chamber from nozzles and meet in the center area, where material would be impacted and ground and sheared. Qualified fine powder would be output and go into cyclone or bag filter, while oversize powder would back to milling area to be milled again.

| Parameters/specifications | MQP03 | MQP06 | MQP10 | MQP20 | MQP40 | MQP60 | MQP80 |

| Feed Size(mm) | <5 | <5 | <5 | <5 | <5 | <5 | <5 |

| Product Size(d97:μm) | 8~150 | 8~150 | 8~150 | 8~150 | 10~150 | 10~150 | 10~150 |

| Production Capacity(kg/h) | 5~100 | 10~200 | 20~400 | 50~800 | 150~1500 | 300~2000 | 400~6000 |

| Air consumption(m3/min) | 3 | 6 | 10 | 20 | 40 | 60 | 80 |

| Air Pressure(Mpa) | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 |

| Installed Power(kW) | 26~37 | 47~68 | 68~106 | 145~184 | 276~310 | 402~427 | 520~600 |

Note:The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.